The world is looking for a solution to the end of oil, climate change, pollution, and poverty. We have it. Bill Gates once said that if he had a superpower, it would be the ability to create a source of energy cheaper than coal with no carbon footprint. Through cumulative knowledge, applied science, and willful determination, we have created a visionary solution.

This is a practical, technically sound, economically viable solution designed to break the strangle-hold of fossil fuel. It is a complete system that will produce enough energy to replace oil, coal, natural gas, and virtually all carbon-based fuel. This system is almost 100 times cheaper than coal, over 160 times cheaper than natural gas, over 200 times cheaper than oil, and will stimulate the world’s economies for decades. This will not only make more money than the industrial revolution, but will also reduce the giga-tons of greenhouse gas emissions we currently produce a year down to zero. We don’t have to replace existing buildings. We don’t have to give up internal combustion engines. We don’t have to give up airplanes. We don’t even have to give up cows. Last but not least, we don’t have to wait decades for a solution. The Hydrogen Solution is what the world has been waiting for.

In order to solve the fossil fuel problem you have to understand the scale of the problem. We currently consume about 100 million barrels of oil a day. When we include all forms of fossil fuel, we begin to approach 500 quadrillion BTU (British Thermal Unit is a measure of the heat content of fuels or energy sources) of energy. In order to replace 500 quadrillion BTU of fossil fuel energy, we have to produce 500 quadrillion BTU of replacement energy.

The reason The Hydrogen Solution works is because IT IS A COMPLETE SYSTEM

When Edison invented the viable light bulb, he stood in a lab with a light bulb in his hand. Not one single person in the world needed a light bulb because there was no place to screw one in. There were no lamps, no outlets, no electric cords, no electric meters, no generators sending power to people, nor an electric grid. Edison had to develop over 480 different inventions to create the electrical system as we know it. After devising a commercially viable electric light bulb on October 21st of 1879, Edison developed an electric “utility” to compete with the existing gas light utilities. On December 17th of 1880, he founded the Edison Illuminating Company. And during the 1880s, he patented a system for electricity distribution. The company then established the first investor-owned electric utility in 1882 on Pearl Street Station, New York City. Finally, Edison switched on his Pearl Street generating station’s electrical power distribution system on September 4th of 1882 to provide 110 volts of DC (direct current) to 59 customers in lower Manhattan.

The Hydrogen Solution is a global solution, a culmination of the same kinds of thought and effort, involving hundreds of technical solutions that have been developed over more than a quarter of a century, designed to utilize Hydrogen as a source of fuel. This system includes more inventions than the 80,000 inventions Mercedes Benz has had in their 125 year history. We will, in fact, have to hire a team of patent attorneys just to handle the volume of inventions incorporated in this entire system.

Scientists around the world are aware of the fact that hydrogen is the most abundant element in the universe. They also know that pure hydrogen is without question the best fuel that can possibly be used. However, what they don’t know is the means to produce it economically in sufficient quantities. Fortunately, we do.

Most preconceived notions about hydrogen are misconceptions.

What most people may not know is that when they start their car, truck, plane, or train and burn fossil fuels, the only thing that is actually being burned is hydrogen. Every single BTU of energy we produce today from fossil fuel is derived from hydrogen; it just happens to be locked in an organic molecule called hydrocarbons.

The problem with hydrocarbons becomes apparent when several pounds of C02 are produced when a pound of fossil fuel is burned. This process is killing us. Sadly, that doesn’t seem to matter to the powers at large. However, now that the number one oil producer in the world–Saudi Arabia–is running out of oil, it matters.

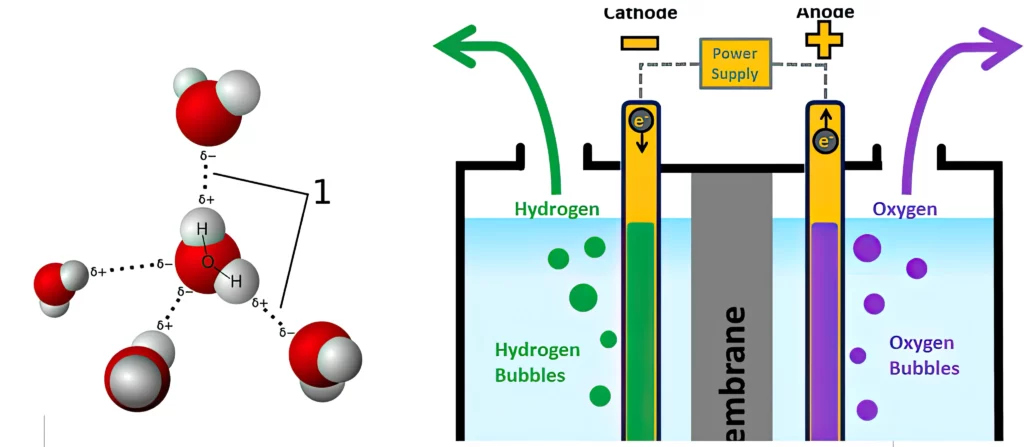

Currently, the process of using fossil fuels to generate the electricity required to produce hydrogen through electrolysis creates and releases more carbon emissions than burning fossil fuel itself. Ultimately, the aforementioned system is too inefficient because of the need to burn many units of fuel to produce one energy unit of hydrogen.

It is important to note that our Hydrogen Solution may be falsely assumed to be like other systems. An example of this would be tidal current generators. In 2004, we saw where a company basically stuck an airplane propeller on a stand attached to the sea floor in tidal currents in order to generate electricity. The complaint was that the system was too expensive; the cost of parts and maintenance required to make it work were uneconomical. Putting an airplane propeller on a stand in the tidal current is completely impractical.

When we say our hydrogen machines sit in the water, some people may assume that it applies the same concept. This comparison, however, would be like comparing a kite to the space shuttle. Tying a piece of paper to a stick on a string will not make it fly 17,000 miles an hour. The technology involved with our Hydrogen Solution is the Space Shuttle of hydrodynamics. It was precisely designed and engineered to operate in seawater. Our hydrogen machines have one moving part, no wires, and unlike a generator, it will produce pure hydrogen and not electricity.

Replacing the energy derived from fossil fuels presented some of the greatest engineering and economic challenges imaginable, such as: where does this new energy come from?

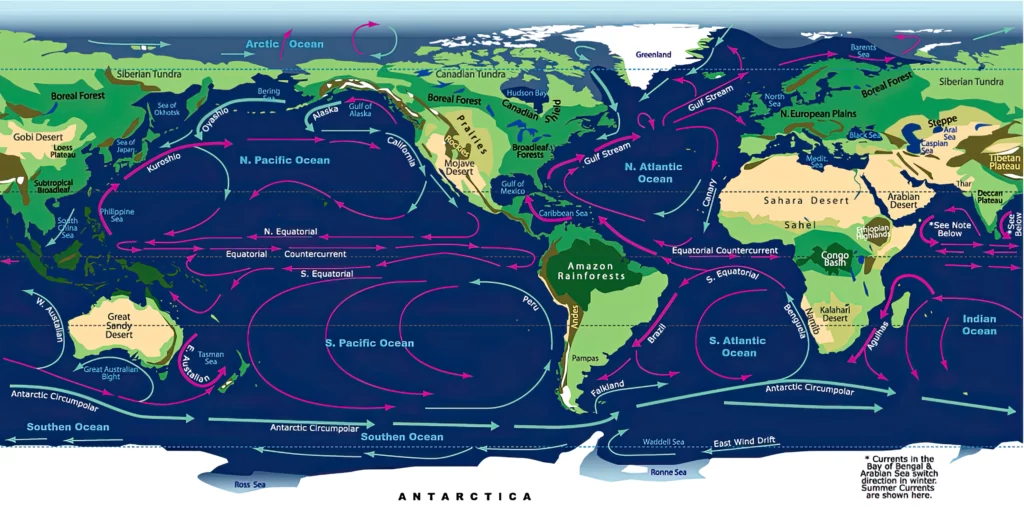

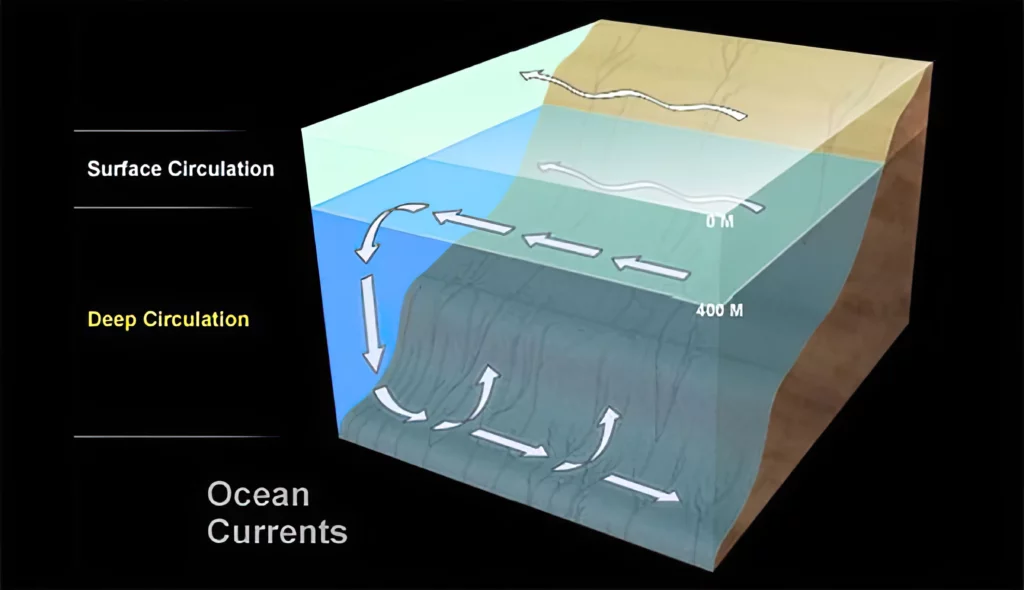

Each hour the sun shines on the surface of the Earth with more energy than is consumed by all of mankind in a year. More than 70% of the earth’s surface is covered with water. The sunshine (thermal energy) heats up the water, causing the warm water to rise to the surface. The warm water then migrates to the poles where it cools, which then sinks down causing convection. When these cold and heavy currents encounter the topography of the ocean floor, they form a system of currents called the “oceanic auger system” which circumnavigates the globe. These huge underwater rivers contain unimaginable amounts of kinetic energy – in colloquial terms, power: more than enough power to power the entire world many times over. The sun, which is the only working fusion reactor, is what we have figured out how to harness and convert into portable motor fuel.

The edge of each continent has a continental shelf that extends an average of about 200 miles out. The average depth at the edge is about 600ft. Then there is a precipitous drop called the abyssal drop that goes down an average of 10,000 feet to the edge of the ocean floor called the abyssal plane. This abyssal wall skirts the edge of the continents forming a solid barrier. When the convection currents encounter this barrier, they follow it.

The ocean floor has mountains just like the surface and when a mountain range is appropriately positioned close to the abyssal drop, they form acceleration zones. These acceleration zones cause the water to travel at speeds between 5 and 10 knots, (about 5-10 mph) 1 Knot = 1.15 mph

It was necessary to invent dozens of new technologies to solve these challenges, including but not limited to:

I have also developed safe and practical storage capacity to scale, compiling the “end user solutions” which include the following:

The complete list is extensive.

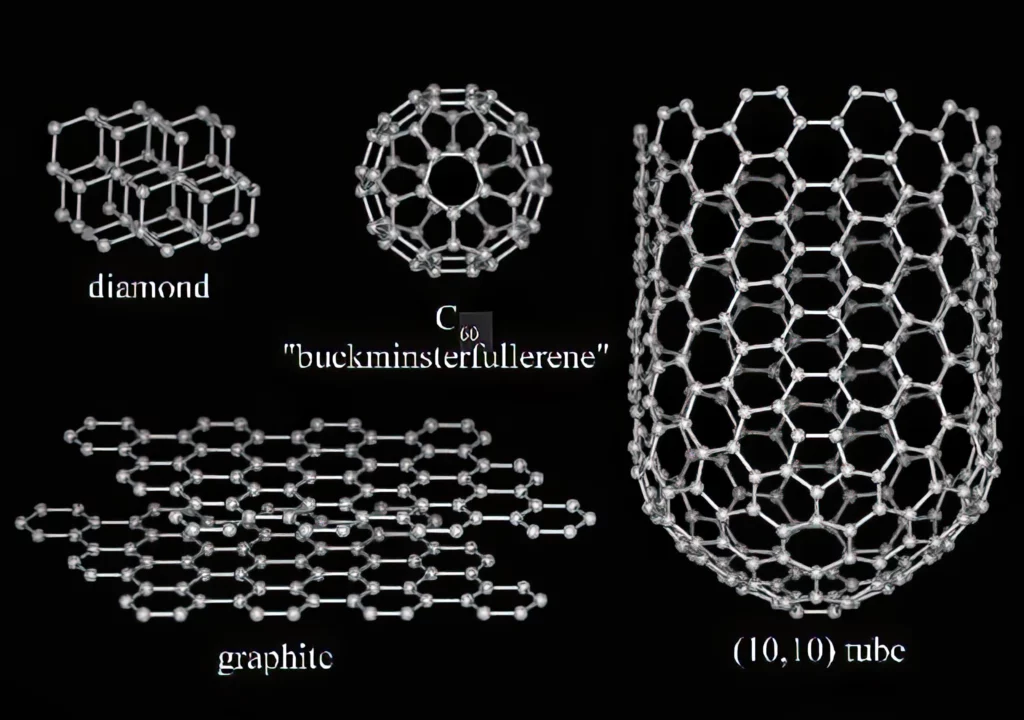

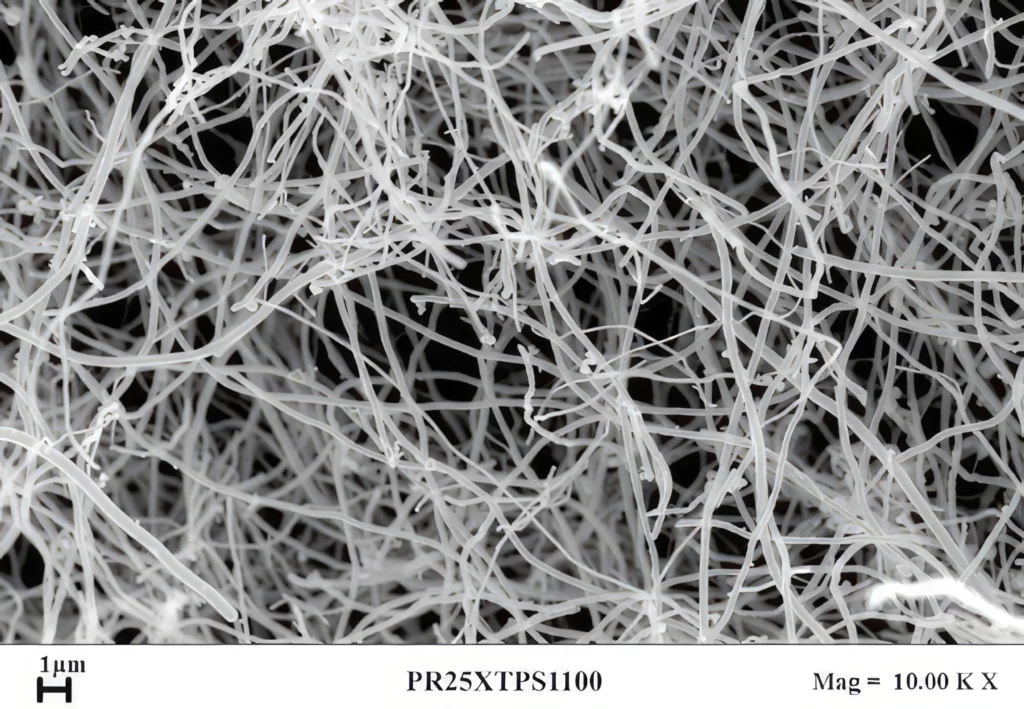

The previous drawbacks to hydrogen powered vehicles were capacity, pressure, and safety of hydrogen storage tanks. These problems have not only been addressed, but also solved. Hydrogen can be stored in a semi-solid state that is both safe and practical. Our tanks contain Graphite Nano Fibers which store 25 times more hydrogen in a given space. The process developed to make Graphite Nano Fibers economically ended up being one of those Alpha-Barrier-Technologies (a technology that completely changes the entire world). In lieu of this advancement in technology, we have invented completely new industries to produce the Graphite Nano Fibers in commercial quantities economically.

With hydrogen powered technology, not only can you drive about twice as far utilizing hydrogen instead of gas, but you can also apply this technology to commercial and military flight applications. We need not sacrifice our quality of life to save the earth and eliminate carbon emissions.

The machines we designed can produce two thousand kilos of hydrogen per hour, 24 hours a day, seven days a week, 365 days a year. That is 48,000 kilos a day per machine. Half of that fuel — 24,000 kilos a day per machine — will be sold as portable motor fuel. 167,000 such hydrogen machines will make over 4 billion kilos of hydrogen a day to sell as portable motor fuel and 4 billion kilos a day we keep for our own commercial purposes.

The high-tech manufacturing facilities we designed will produce 25 units per week, which amounts to 1,300 units per year. Fifty manufacturing facilities worldwide will produce 65,000 units per year. Consequently, it will take about 2 1/2 years to produce the units once the facilities are up to capacity. These units will produce enough hydrogen to completely replace fossil fuels. At that point, we will reduce Global Carbon Emissions from fossil fuels to zero. We will continue to produce more units until we reach 20 billion kilos of hydrogen a day, more if needed. Ultimately, we are preparing for the increase of energy demands in the future.

This is the next great technical revolution. Wood was the original fuel, followed by coal, progressing to oil. The next step in the evolution of fuel is hydrogen, not from methane, ethane, propane, nor butane, but from hydrogen procured from water. The power for electrolysis will be harnessed from the kinetic energy made available through the movement of convection currents—huge rivers of nearly unlimited power—in the ocean. The Hydrogen Solution system is unique. It is more, if not as avante garde as the first plane built by the Wright brothers and as the utilization of electricity by Tesla and Edison.

All details related to production, transportation, storage, and end user requirements have been addressed. We have either invented or acquired all the creative solutions from the cross-application of existing technologies. Skunkworks produced the SR-71 Blackbird, which flew in 1963. It was so far advanced it remains to this day among the fastest and hard to believe. Our hydrogen system is the SR-71 of systems. It is so far ahead of current technology and current thinking that people will find it hard to believe.

Good engineers solve big problems with complex solutions you could never understand. Great engineers apply such simple solutions that you can’t believe you didn’t think of them yourself. We accomplished both several times over in order to overcome the obstacles and develop The Hydrogen Solution.

In order for this to work at all we had to make it profitable. Because let’s face facts: money makes the world go round. If we want the world to help, we have to make money.

This system will produce virtually unlimited hydrogen for 0.75 cents per kilo. It currently costs about 40 dollars a barrel to pump, ship, and refine a barrel of oil. That same 40 dollars will produce 5,333 kilos of hydrogen. A kilo of hydrogen is the same as a gallon of gas. Imagine making over 5,000 gallons of gas for 40 dollars with no pollution and no refinery. From a strictly economic perspective, it would be absurd not to make hydrogen. Hydrogen produced our way is many times more profitable than any fossil fuel. At target capacity we can produce over 20 billion kilos a day, more if necessary. At just 1 dollar per kilo, just half of the 20 billion kilos is 10 billion dollars a day in revenue. And that is only a 1 percent fraction of the money this entire system will produce, which should be plenty to inspire the cooperation of the world.

Let’s see if we can give you the gist of it:

Let us paint a mental picture together.

Let’s say you have two gas cans, each can containing 1 kilo of petrol which is equal to 1 gallon of gas. The total cost to produce both kilos is 1.5 cents. One of those kilos you sell as portable motor fuel to a consumer for 1 US dollar, recovering the 1.5 cents and making 98.5 cents in profit. The other can was paid for by sale of the first can and you can now think of the second can as “virtually no cost fuel”. Being able to think of our second kilo as “virtually no cost” frees our mind to think outside the toxic box. That “no-cost” energy we use for the solution to our material cost problem.

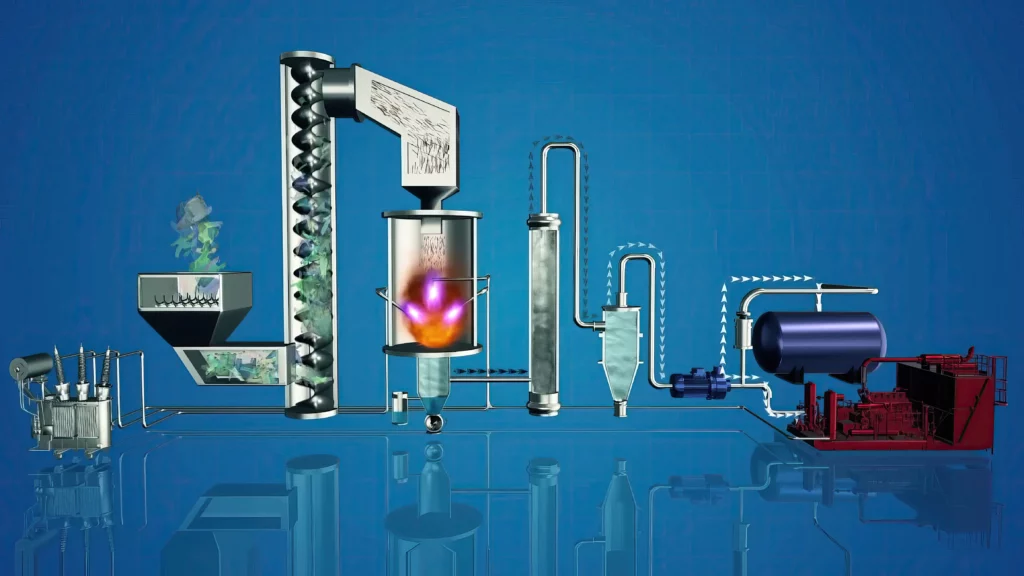

The solution to our material cost problem is called the “Plasma-Arc Waste Management System” or P.A.W.M.S for short. P.A.W.M.S. utilizes trash and waste that would otherwise go into a landfill or be dumped into the ocean by heating it up to the 4th state of matter called plasma to achieve “molecular dissimilation”, thereby separating it into its individual atoms. We then put to use physics and proprietary technology that already exists to capture those atoms in commercially viable quantities. Picture the entire periodic table of elements up to 92 being stored in their respective large commercial vats.

We can then combine them with conventional chemistry to produce any material we need at virtually no cost. In fact, we profit from it without creating unwanted pollution or byproducts. Here’s how and why it took over 25 years to engineer this solution.

In the United States a typical family has their trash removed by a waste management company. These companies pay an average of 60 dollars a ton to dump the removed waste at a landfill. The average American produces about 4.5 pounds of trash a day, which collectively adds up to 742,500 tons a day, assuming there are about 330 million Americans.

Now, if we were able to tell all of those waste management companies that they could bring their trash to us for only 30 dollars a ton, how many of them would bring their trash to us? The answer would be a resounding: all of them. That is $22,000,000 a day. That means if we build the right infrastructure, we can generate $22,000,000 a day to pay the wages and fixed costs of operating the Plasma Arc Waste Management System. Since the total cost of obtaining the trash is less than zero, our cost of converting the trash to atoms and subsequently into materials is essentially zero. Hence, what we end up with is virtually no-cost energy and virtually no-cost materials for our industrial purposes. Imagine the industrial competitive advantage this represents. Keep in mind that these numbers are easily reached on a global scale.

In 2014, a Z06 Corvette luxury model sold for about 125,000 dollars and is made from approximately 14,000 parts all manufactured throughout the world. It costs about 85,000 dollars to purchase and logistically move those components to assemble the car. With our technology, we could produce an exact duplicate of that same car down to the atom for about 66 dollars. Can you imagine the industrial competitive advantage GM, Ford, or Boeing would have if they had this technology? Is our car company going to beat their car company? How about our plane company, our train company, or even our computer company? The same thing applies to everything in the world across the entire spectrum of human endeavor and all industries. That represents more IPOs than the entire industrial revolution. Our financial services and investment banking division will exceed the entirety of current world markets.

This technology was developed to solve a technical problem in the manufacture of advanced materials. To produce Graphite Nano Fibers, carbon-carbon, and carbon fiber components using conventional means can cost up to 1,500 dollars a gram. Some of the more complex systems require tons of exotic materials and rare-earth elements. To obtain these exotic materials through conventional means made the entire system prohibitively expensive. Fortunately, the Plasma Arc Waste Management System technology will solve the economic problem for our proprietary systems. Moreover, we will be able to apply it economically and sustainably across all industries.

The economic stimulus from this technical revolution will be like nothing ever seen before. The business opportunities involved in moving from fossil fuel to hydrogen will stimulate the world’s economies for decades. Those witnessing the economic boom will be thunderstruck by the scale and duration. The nice thing is that everyone will benefit. Everyone on Earth and the Earth itself will benefit from this in ways at first difficult to imagine. Clean, abundant, affordable, profitable and infinitely sustainable power that leaves no carbon footprints can now be achieved. Not since the invention of electricity have we had such a grand theme that means everything to everyone. However, we can’t make The Hydrogen Solution a reality without your help.

The world needs to be made aware of all the aforementioned possibilities so we can put together a team to make our Hydrogen Solutions a reality. Those who join and sow seeds into our team during its genesis will be able to reap the greatest of benefits during and at the completion of The Hydrogen Solution.

We are the first species that will document and record our own extinction if we don’t solve this problem. Every day we let this problem continue, we are committing geopolitical suicide.

God willing, we WILL come together and implement this plan. We WILL implement a solution that improves the life of every organism on this planet. We WILL leave a sustainable legacy of prosperity for future generations allowing them to be responsible stewards of the earth. Last but not least, we WILL be the greatest generation that faced and overcame the greatest challenge in human history.

“Sometimes it’s the people you imagine nothing of who do things you can’t imagine.” – Steve Jobs

Join Earth Club! Empower us to transform the current problems and limitations of our world into the fuel for The Hydrogen Solution. Dismiss